Kakaretso:Ho ile ha hlahlojoa mokhoa oa ho etsa le likotsi tsa varnish ea oli e tlotsang. sethaleng. mokhoa le lisebelisoa li na le phello e ntle ho ntlafatseng bohloeki ba oli le ho tlosa litšila tse ntle.

Mantsoe a sehlooho:turbine ea khase; varnish ea oli e tlotsang; tlhahlobo ea MPC; ho hloekisa adsorption; resin ea phapanyetsano

turbine ea khase ke e 'ngoe ea lisebelisoa tsa mantlha tsa sethala sa offshore.E sebelisoa e le lisebelisoa tsa ho fehla motlakase sethaleng sa offshore ho netefatsa ts'ebetso e tsitsitseng le e telele ea potoloho ea turbine ea khase bakeng sa ho netefatsa tlhahiso e tloaelehileng ea sethala sa offshore.Mochine oa khase o boemong ba mocheso o phahameng, khatello e phahameng le lebelo le phahameng nakong ea ts'ebetso, 'me li-varnish li bonolo ho hlahisoa sebakeng sena.Ka nako e ts'oanang, ka ntlafatso ea boleng ba oli ea mantlha ka oli e tlotsang, bokhoni ba ho tlotsa li-varnish bo senyeha, e leng ho matlafatsang sebopeho se potlakileng sa varnish.Ho thehoa ha varnish ho baka ho bokellana ha varnish, kotsi e kholo ho lisebelisoa, e tla baka ho fokotseha ha tumello, ho eketseha ho apara, lisebelisoa tsa ho khomarela lisebelisoa tsa valve ha li tsitsitse ebile li hlōlehile;varnish e behiloeng holim'a shaft, pholileng le likarolo tse ling e baka ho fetoha ha mocheso oa sekhahla sa phapanyetsano ea mocheso oa shaft, ho potlakisa ha oxidation ea oli: varnish e tla khomarela likaroloana tse tiileng, e thibele karolo ea filthara le lesoba la throttle, e leng se fellang ka ho roala ha lisebelisoa le lisebelisoa tse fokolang. lubrication, turbine ea malapeng le kantle ho naha ho hloleha ho hloleha ho sa tloaelehang ha pente ho etsahala.Leqepheng lena, mongoli o hlahisa mathata a sa tloaelehang joalo ka ho lemoha tloaelo ea sethala sa Huizhou 32-2 sethala sa jenereithara sa solar gas turbine, se tšohla ts'ebeliso eayuniti ea ho tlosa varnishsetsing sa sethala, 'me e fana ka litšupiso tse ling bakeng sa basebetsi ba tlhokomelo ea lisebelisoa liindastering tse amanang le taolo ea lisebelisoa tse tlotsang varnish ea oli.

1 Mochine oa sebopeho le kotsi ea ho tlotsa varnish ea oli

1.1 Tlhahlobo ea filimi ea oli e tlotsang

varnish ke polymer, ke oxidation ea lintho tsa oli, mmala ho tloha leseli sootho, sootho ho tan, moloko oa eona oa lebaka le ka sehloohong ho na le likarolo tse tharo.

(1) Oxidative le degradation ea lihlahisoa tsa oli: lihlahisoa tsa oli li ntse li sebelisoa thupelong.Lithempereichara tse phahameng, metsi, litšepe le moea kaofela li potlakisa oxidation, ho hlahisa asiti ea carboxylic, ester, joala le lihlahisoa tse ling tsa oxidation, le mofuta o mong oa condensation Ka polymer: ho feta moo, antioxidant ea amine ka oli e boetse e bonolo ho hlahisa varnish.

(2) Libaka tse chesang tsa sebakeng sa heno le li-microcom bustion li baka oli ea motheo kapa ho senyeha ka potlako ha mocheso oa li-additives ho etsa li-varnish, mocheso o phahameng kapa khohlano ea matla a phahameng Karolo ea tšepe e nang le mocheso o phahameng haholo (e tloaelehileng joalo ka sehlahla se behang), e leng se bakang Mocheso oa mokelikeli o kopanang le sebaka o phahame haholo, o etsa hore mokelikeli o Potlakile ho senyeha ha mocheso ho hlahisa li-varnish, 'me li khomarele habonolo likarolo tsena Ho thehoa ha ho bokella;ho tlotsa oli tabeng ea compression bohale e boetse e ho le bonolo ho hlahisa micro Combustion ketsahalo, ho hlahisa e nyenyane haholo boholo ba lintho tse insoluble, khomaretse holim'a tšepe sebopeho varnish, bapisoa le moloko oa pele oa oxidation degradation, moloko oa bobeli oa. penta Lebelo la lera le tla ba kapele haholo.

(3) Ho tsoa ha spark le hona ho tla theha varnish, haholo ha oli e feta ka har'a ntho e 'ngoe e rarahaneng ea filthara ho hlahisa static current, ts'ebetso ea spark discharge e etsa hore ho bokelloa ha varnish habonolo.

1.2 Kotsi ea ho tlotsa varnish ea oli

Ho bokellana ha li-varnish holim'a lehlakoreng la khohlano ho tla fokotsa lekhalo la filimi ea oli, phetoho ea mocheso oa mocheso Ho futsanehile, ho senyeha ha metsi a lubricating, ho etsa hore mocheso o thusang oa ho ferekanngoa o phahame haholo Phahameng, tšenyo e matla ea ho kopana le holim'a metsi;turbine ea khase e lula e bulehile 'me e emisa boemo ba ho sebetsa, phetoho ea mocheso oa oli e ka baka sebopeho sa varnish , varnish e entsoeng e ka khomarela habonolo likarolo tse rarahaneng, tse kang hydraulic servo valve, e fellang ka ho thibela valve, valve. karete ea bond ea mantlha e shoele, ho hloleha ho laola esita le ho tlola lisebelisoa;varnish e boetse e etsa hore phello e pholileng ea pholileng e fokotsehe, ho thibela lintho tse hloekisang, ho se be le lubrication ho mpefatsa le ho potlakisa sehlahisoa sa oli le litlamorao tse ling.

2 Litekanyetso tsa tlhahlobo ea index ea Varnish

Hajoale, mokhoa oa ho lekanya index ea li-varnish tsa oli ke ASTM D7843 "purifier membrane photometric analysis (MPC) e sebelisoang Mokhoa oa teko bakeng sa thepa e sa keneng ka har'a oli ea mouoane.Liphetho li tlalehoa e le pente Membrane tendency index AE.Molao-motheo oa mokhoa ona ke ho sebelisa vacuum filtration system Tlosa seretse le gelatin sehlahisoa sa oli 'me u se behe ka har'a lera le hloekileng la ho hloekisa holim'a poleiti (lekana la purifier membrane aperture 0.45 p, m), sebelisa purifier ka mor'a hore poleiti ea purifier e omisitsoe. Filimi ea chromaticity tester ho lekola boleng ba eona ba MPC (AE).Lera la purifier le ne le behiloe Ha u fumana lintho tse ngata.Ha 'mala o le lefifi, ho na le index e kholo ea li-varnish.Ha phetoa

Keketseho e tsoelang pele ea boleng ba MPC (AE) e lokela ho etsa hore basebetsi ba molaoli oa thepa kapa basebetsi ba tlhokomelo ba e ele hloko.

3. Tšebeliso ea mochini o hloekisang oli ea varnish

3.1 Boemo ba hajoale ba oli e tlotsang pele o sebelisa mochini o hloekisang oli ea varnish

Seteishene sa jenereithara ea turbine ea sethala sa Huizhou 32-2 ke yuniti ea Solar T60,

Sheba Lethathamo la 1 bakeng sa lintlha tse ikhethileng tsa oli e tlotsang pele u sebelisa mochini o hloekisang.

| Lethathamo la 1 Lintlha tsa tlhahlobo ea oli ea turbine pele e sefshoa | ||

| Morero | Lintlha tsa ho hloekisa pele | Reference value |

| mohlala oa tanka / bokhoni | Bokhoni ba vortex 46 # oli / yuniti ka 'ngoe e ka ba 1800L | / |

| Viscosity ea motlakase ea 40℃ V / (mm² s- ¹ | 45.37 | 41.4-50.6 |

| Boleng ba asiti (ka KOH) w/(mg·g-¹) | 0.18 | ≤0.35 |

| Mongobo c/(mg·L-¹) | 46 | ≤100 |

| bohloeki ISO | 23/21/11 | ≤–/16/13 |

| varnish propensity index / MPC | 31.5 | ≤20 |

Qetello ea setsi sa tlhahlobo ea mokha oa boraro ke ka tsela e latelang: boleng bo phahameng ba li-varnish index, tafole ea oli e khanyang e na le palo e kholo ea lintho tse sa tsitsang tsa polar tse nyane tsa molek'hule, ho bonolo ho khomarela tšepe li etsa varnish holim'a metsi, varnish e tla baka khohlano. mocheso oa bobeli ho phahama le ho etsa hore thepa e hlōlehe, lihlahisoa tse phahameng ka ho fetisisa li ka ama botsitso le bophelo ba tšebeletso ea tsamaiso ea karolo e amanang le eona, oli e ka tsoela pele ho sebelisoa, empa e hloka ts'ebetso e phahameng ea ho hloekisa.Sebelisa setsi sa ho tlosa varnish ho tlosa polarity ho tsoa ho solubility ea oli, ho kgothaletswa ho khutsufatsa nako ea sampuli le ho ela hloko bohloeki le boleng ba MPC le liphetho tsa ho shebella index.Ka ho shebella setsing sa lisebelisoa, ho se tsitse ha khatello ea oli e tlotsang ho etsahala ts'ebetsong, e amang ka botebo ho tšepahala ha tsamaiso ea oli e lokiselitsoeng ea oli le likarolo tsa ho laola metsi.

3.2 Molao-motheo le tšebeliso eayuniti ea ho tlosa varnish

Ka lebaka la bothata ba varnish ka oli e tlotsang, likhoebo tse ling li ile tsa nka mehato ea ho fetola oli, empa phello ha e ntle ebile ha se ts'ireletso ea tikoloho.Ho etsa bonnete ba hore jenereithara sete Tšepahala, etsa qeto ea ho lokisetsa bakeng sa yuniti varnish tloswa le filtration mosebetsi.

Melao-motheo ea botekgeniki ea lihloekisi tse 'maloa tsa oli ea varnish e etsoa ho Lethathamo la 2

tlhahlobo ea papiso.

Tlhahlobo e felletseng ea papiso e etsa qeto ea tefo ea adsorption + sefate sa phapanyetsano

Theknoloji ea lipid ho tlosa varnish ho oli.Ka teko ea sebele, ke khethile e le 'ngoe

A WVD e hloekisang oli e hloekileng ea varnish, pokello ea oli e hloekisang tefiso ea tekhenoloji ea adsorption le theknoloji ea adsorption ea resin ho e le 'ngoe, ke ka sefate sa phapanyetsano.

Lihlahisoa tsa varnish lia tlosoa 'me li qhibiliha ka theknoloji ea adsorption ea tefiso

Tlosa varnish e emisitsoeng e entsoeng ka oli le likarolo tse khomaretsoeng filimi.

| Letlapa la 2 Phapang ea mekhoa e fapaneng ea ho thibela varnish | |||

| Sebopeho sa varnish | Resin thekenoloji ea phapanyetsano | Theknoloji ea adsorption e lefisa | Theknoloji ea adsorption + phapanyetsano ea resin |

| Li-varnish tse qhibilihantsoeng ka tharollo ea oli | Ho tlosoa ka resin adsorption | Ha e khone ho tlosa | Ho tlosoa ka resin adsorption |

| Varnish e emisitsoeng ka oli | Ho tlosoa ka mokhoa oa resin reverse dissolution | Ho tloswa ka tefiso adsorption filtration | Ho tlosa ka ho kopanya tekhenoloji ea adsorption le tekhenoloji ea ho qhala resin reverse |

| varnish e khomaretsoeng ho sehlahla se behang le likaroloana | Ho tlosoa ka mokhoa oa resin reverse dissolution | Varnish e khomaretsoeng e ka tlosoa ka mafolofolo ka likaroloana tse qositsoeng

| Varnish e khomaretsoeng e tlosoa ka ho kopanya likaroloana tse qosoang le theknoloji ea ho qhibiliha ea resin reverse |

| Tlhahlobo e felletseng | Ho itšetleha ka resin ho tlosa varnish e qhibilihang, ebe ho tlosa li-varnish tse qhibilihisitsoeng le likarolo tsa li-varnish ka molao-motheo oa nako e telele oa ho qhibiliha ha oli, ts'ebetso e tlaase e tlaase, 'me lisebelisoa tsa resin nakong e tlang li boima. | E ka tlosa li-varnish tse emisitsoeng ka oli le li-varnish tse khomaretsoeng likarolong, hobane phello ea varnish e qhibilihisitsoeng ha e ntle. | Theknoloji ea ho hloekisa ea adsorption e kopantsoeng le theknoloji ea resin adsorption e ke ke ea tlosa varnish e qhibilihisitsoeng ka potlako feela, empa hape e ka tlosa oli e emisitsoeng ka oli le likaroloana tsa li-varnish tse khomaretsoeng, ts'ebetso e phahameng, thepa ea boea e tlaase ea sefate. |

3.2.1 Tefiso ea theknoloji ea adsorption le molao-motheo oa ho sebetsa

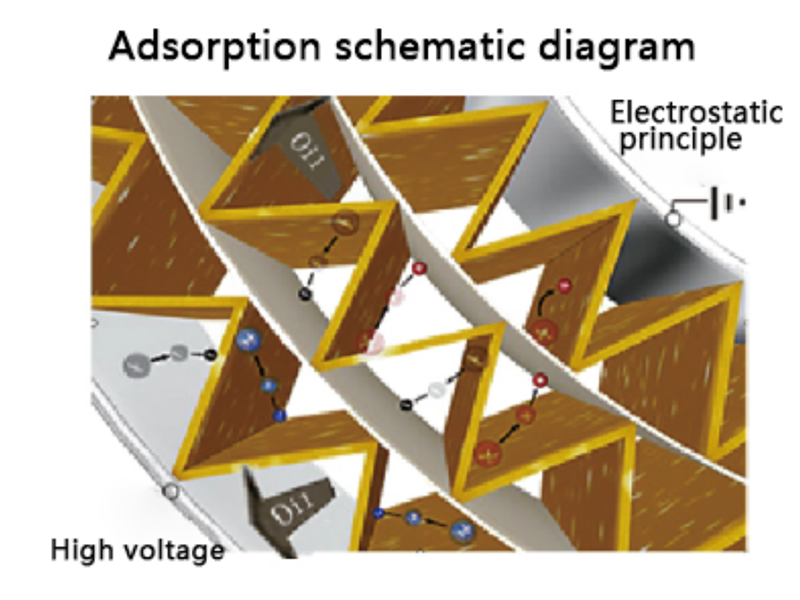

Theknoloji ea adsorption ea charge haholo-holo e sebelisa jenereithara e phahameng ea motlakase ho hlahisa matla a phahameng a motlakase o tsitsitseng, ho etsa hore likaroloana tsa tšilafalo ka har'a oli li be le polarized le ho bonts'a motlakase o motle le o mobe ka ho latellana, likaroloana tsa motlakase tse ntle le tse mpe li lebisitsoe ka tatellano tlas'a ketso ea motlakase o phahameng haholo. lebala la motlakase Li-electrode tse mpe le tse ntle lia sesa, 'me likaroloana tse sa nke lehlakore li hatelloa ke ho phalla ha likaroloana tse qosoang.Qetellong, likaroloana tsohle li adsorbed 'me li khomaretsoe ho mokelli, 'Me ka karolo ea likaroloana tsa oli tse qositsoeng tse sa kang tsa ba le nako ea ho monya phallo, na Mlay litšila, varnish le oxidation khomaretse tanka ea oli, phala lebota le likarolo.

Lintho tsohle li hlatsoa sehlopha sa adsorption (sheba setšoantšo sa 1).Mokhoa ona o ka atleha ho hloekisa Varnish e emisitsoeng le li-varnish tse khomaretsoeng likarolong, bakeng sa ho phahamisa

Bohloeki bo phahameng le bona bo na le phello e molemo.

Molao-motheo oa theknoloji ea adsorption ea tefiso

Molao-motheo oa theknoloji ea adsorption ea tefiso

3.2.2 Thekenoloji e leka-lekaneng ea ho hloekisa tefiso

Mokhoa o leka-lekaneng oa ho hloekisa (Balanced Charge purification) mokhoa ke ho arola mokelikeli o jereng likaroloana tse nyenyane makaleng a mabeli.Lekala Tsela e na le li-electrode tse phahameng tsa motlakase ho kenya tjhaji e ntle le likaroloana tse nyane ka ho latellana Tefiso e mpe: ebe boima ba maro a mabeli ka likaroloana tse fapaneng tsa tefiso.

Kopano e ncha e nyalisitsoeng.Litefiso tse ntle le tse mpe li hohelana 'me li bokana ho theha 'musi o moholo oa likaroloana tse 10;Qetella ka mochini kapa sehloekisi se bohareng.

3.2.3 Theknoloji ea phapanyetsano ea resin adsorption

Ho ke ke ha khoneha hore lihlahisoa tsa varnish tse qhibilihisitsoeng li itšetlehe ka theknoloji ea adsorption ea tefiso

ho tsholla.Thepa ea resin e lokiselitsoeng ka ho khetheha ke sehlahisoa se qhibilihisitsoeng (se boetse se bitsoa lacquer film embryo) se fana ka sehloeki se mahareng se nang le kamano e phahameng, se sebelisa resin Lihlopha tse ruileng tsa thepa ea adsorption li ka khahla mefuta eohle ea tlhahiso ea litšila hantle haholo.Kahoo ho na le sekhahla se phahameng sa ho tlosoa ha lihlahisoa tsa varnish.Thepa ea resin adsorption E ntle ea thepa e tsitsitseng, ho hanyetsa mocheso o phahameng, tšebeliso e ke ke ea e-ba le lihlahisoa tse senyang le ho oa Lintho li kena ka oli.Ho phaella moo, tšebeliso ea thekenoloji ea resin reverse dissolution (tšepa sefate Ka mor'a hore lipid e tlose filimi e qhibilihisitsoeng ka oli, filimi e emisitsoeng ka oli 'me e khomaretsoe Ka li-varnish ho likarolo li tla khutlisa ho qhibiliha ho khutlela ka oli hore e qhibilihe. varnish, Ebe e tlosoa ka resin adsorption), bakeng sa oli ka boemo ba ho fanyeha varnish le khomaretse Likarolong tsa varnish e boetse e na le phello e itseng ea ho tlosa.

3.2.4 Phello e khethehileng ea ts'ebeliso ea ho tlosa mochini o hloekisang oli ea varnish

Ka WVD mochini o hloekisang oli o hlakileng oa varnish sethaleng sa 32-2 Solar The T60 unit e ile ea hloekisoa ka nako e ka bang matsatsi a 10.Ho tharollo ea oli e hloekisitsoeng Lintlha tsa liteko tsa sampole li bonts'itsoe ho Lethathamo la 3.

| Letlapa la 3 Lintlha tsa tlhahlobo ea oli ea turbine ka mor'a ho sefa | ||

| Morero | Lintlha tsa ho hloekisa pele | Reference value |

| mohlala oa tanka / bokhoni | Bokhoni ba vortex 46 # oli / yuniti ka 'ngoe e ka ba 1800L | / |

| Viscosity ea motlakase ea 40℃ V / (mm² s- ¹ | 45.43 | 41.4-50.6 |

| Boleng ba asiti (ka KOH) w/(mg·g-¹) | 0.12 | ≤0.35 |

| Mongobo c/(mg·L-¹) | 55 | ≤100 |

| bohloeki ISO | 15/13/9 | ≤–/16/13 |

| MPC | 4.4 | ≤20 |

E fumanoa ka mokhatlo oa boraro oa ho hlahloba oli.lube Ka mor'a ho hloekisoa, tloaelo le bohloeki index ea filimi pele ho hloekisoa ho totobetse Ntlafatso, boleng ba acid le bona bo fokotsehile haholo;le hoja metsi a eketsehile hanyenyane, empa Ha ho nahanoa hore phoso ea ho lemoha le lintlha tse ling li ntse li le ka har'a sebaka se tšoanelehang, kahoo ha se nkoe e le motheo oa Tlhahlobo ea litšupiso;litsupa tse ling kaofela li tloaelehile, 'me sephetho sa teko sea tšoaneleha.Ka nako e ts'oanang ho hlaka Khatello ea ho laola oli ea lubricating ha e tsitsa nakong ea ts'ebetso ea "varnish purifier" Ntlafatso e kholo, 'me phello e totobetse.

4 Qetello

Mokhoa oa ho kopanya adsorption ea tefiso le sesebelisoa sa resin ea phapanyetsano e ka ntlafatsa haholo tloaelo ea litekanyetso tsa oli ea turbine ea khase le matšoao a tekanyo ea tšilafalo.Kenya yuniti ea Solar T60 sethaleng sa 32-2 ka mor'a ho sebelisa sesepa sa oli ea ho tlosa varnish ka letoto la WVD.Lipontšo le bohloeki ba yuniti e tlotsang oli ea varnish e ile ea ntlafatsoa mme ea khutlisetsoa sebakeng se loketseng, ea fihlela phello e lakatsehang, ea thibela sebopeho sa varnish, tse ling tse ling tsa 'mele le tsa lik'hemik'hale Index e boetse e ntlafalitse, haholo-holo khatello ea taolo ea oli e tlotsang yuniti. ts'ebetso ea ho se tsitse ha matla le eona e felisitsoe, ho netefatsa ts'ebetso e tsitsitseng ea sehlopha.Ho phaella moo, mochine oa ho tlosa li-varnish o sebetsa ka mokhoa o tsitsitseng tikolohong e thata, phello e totobetse, litšenyehelo tsa morao-rao tse sebelisoang li tlaase, li na le ts'ebetso e ntle.

Nako ea poso: Mar-15-2023